Types of FRP rebar show different performance compared to traditional building materials such as steel and aluminum. These rebars have high strength although they are low in density. The resistance of all types of FRP rebar against corrosion is extraordinary and…. The types of FRP rebar are different based on the fibers used in their structure. Next, various types of composite rebar with glass, carbon, Aramit, and basalt fibers have been investigated.

Fibers of Types of FRP Rebars

The choice of fibers will play a decisive role in the properties of FRP rebar. Carbon, glass, and aramid fibers are the three fibers used in the rebar structure, and basalt fibers are recently used in composite rebars. The most important difference between the types of FRP rebars is their tensile strain and hardness.

glass fiber carbon fiber aramit fiber

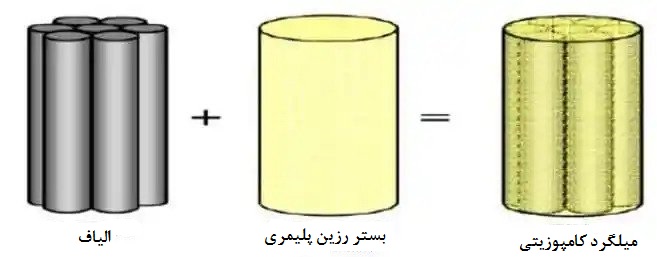

Polymer Resin Substrate of Types of FRP Rebar

The polymer resin substrate must transfer the forces between the fibers and protect the fibers. Thermoset resins are used in most productions of FRP rebars. Vinyl ester and epoxy are the most common polymer resin substrates. Epoxy is usually preferred over vinyl ester, but it also costs more. Epoxies have good strength, adhesion, creep properties, and chemical resistance.

Fibers Polymer resin substrate Composite rebar

Uses of Types of FRP Rebar

Structures often require maintenance under environmental stress. Especially in the vicinity of humidity, rusting and corrosion of steel is not far from expected. For a long time FRP fibers have been used to strengthen structures and various types of FRP rebars have also been widely used to strengthen structures.

The first cases of using FRP rebars to strengthen the structure date back to the 1960s in America. The process of academic research and development of regulations continues until the 1980s. However, the turning point of using FRP rebar can be seen in the Japanese transportation industry. Magnetic trains were developed in Japan in the 1990s, and the use of steel rebar interfered with the operation of magnetic trains. The Japanese formed the first FRP-reinforced concrete design team, and since then, the use of FRP rebars in the world has developed significantly. FRP reinforcements were mainly replaced and stabilized quickly in structures that were subjected to severe corrosion or structures that dealt with magnetic fields.

Advantages of Types of FRP Rebar

Unlike steel rebars, FRP rebars are non-corrosive and resist reaction with chloride. Undoubtedly, a structure that is in contact with moisture and especially salt water, reacts with the sodium chloride in water, and you will soon witness severe corrosion of steel, but if FRP is used, corrosion will not be a worry. In addition, the weight of FRP is relatively lighter and is acceptably strong.

In terms of mechanical properties, the elastic modulus of FRP is usually lower than that of steel (of course, CFRP carbon rebar has a high Young’s modulus). Types of FRP rebars with linear elastic and no yielding stage, have a lower elongation rate and their failure strain is lower. The feature of “fatigue” is seen less in the operation of all types of FRP rebar, which is important in the usage quality stage of operation.

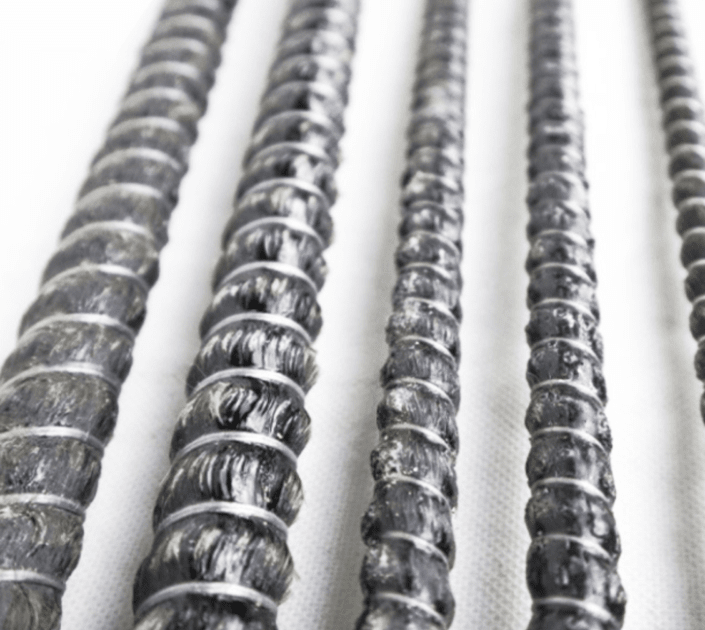

Types of FRP Rebar

The Structure of Types of FRP Rebar

The composite required for the production of FRP is usually created by combining several materials of different properties. FRP composite is generally produced using fiber, resin, fillers, and additives. The fiber used in these rebars has a high elastic modulus and contributes to the mechanical properties of FRP. At the same time, the resin used in all types of FRP rebars facilitates the transfer or distribution of stress from one fiber to another fiber so that the rebar structure is safe from mechanical damage. The interface used between the fibers affects the safe operation of all types of FPR rebars, and fillers help to reduce the shrinkage of the rebars. In addition to improving the efficiency of the rebar, the additives also significantly improve the physical and mechanical properties.

The 4 main materials used in the production of FRP rebar include:

- Carbon

- Glass

- Aramid

- Basalt

All kinds of FRP rebars are produced using these materials, the names of which are as follows:

- CFRP : Composite rebars that use carbon in their structure

- GFRP : Composite rebars that use glass in their structure

- AFRP : Composite rebars that use aramid in their structure

- BFRP : Composite rebars used in basalt element in its structure

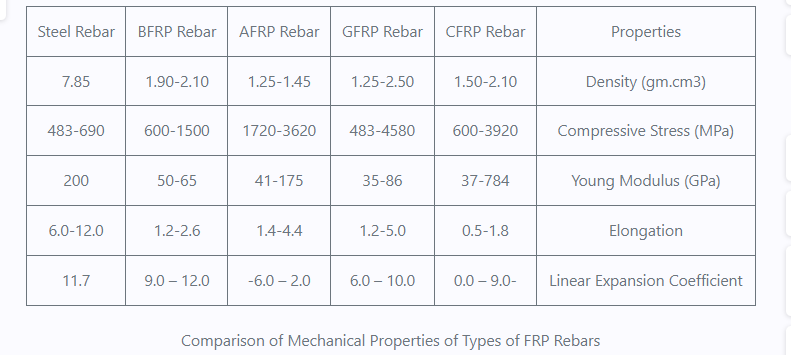

Mechanical Properties of Types of FRP Rebar

The mechanical properties of 4 composite rebars compared to steel rebars are presented in the following table:

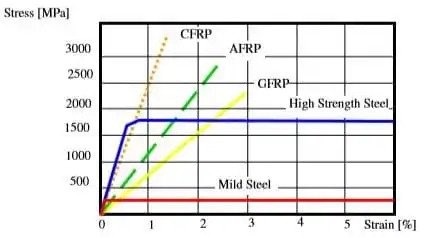

Stress-Strain Curves of Types of FRP Rebars

As the graph below shows, the stress-strain ratio of types of FRP rebar compared to steel rebar indicates the removal of the plastic zone. Another point is the high elastic modulus of carbon fiber rebars (CFRP), which equals the most resistant steel rebars up to the breaking point but does not enter the plastic region like other composite rebars. The following graphs show that when the stress is below 250 megapascals, the amount of strain of FRP rebars is almost equal to that of steel rebars, and as the stress increases, the strain of composite rebars increases greatly.

Stress-Strain Curves of Types of FRP Rebars

CFRP Rebar

Carbon fibers are anisotropic material produced at high temperatures. Regarding the main features of this fiber, one can mention low density, poor conductivity, high resistance to fatigue, high elastic modulus, good creep level, and resistance to chemical effects and lack of water absorption. However, high compressive strength should not be expected from CFRP rebars, and the anisotropy has led to a decrease in the radial strength of these rebars.

Types of FRP Rebars Produced with Carbon Fibers

Carbon fibers have a high elasticity modulus (200-800 GP) and the final elongation of these rebars is 0.3-2.5%. Less elongation means more stiffness. Carbon fibers do not absorb any moisture and are resistant to many chemical solutions. These rebars resist fatigue well and do not suffer from corrosion and do not show any signs of creep.

FRP Rebars Produced with Carbon Fibers

GFRP rebar

One of the most famous and widely used composite rebars is the GFRP rebar, in the structure of which glass is used. This rebar is also called fiberglass. Glass fibers are isotropic and have wide applications. Types of GFRP rebar have high strength and are completely resistant to water and chemical corrosive substances. The production cost of these rebars is lower than carbon rebar.

One of the disadvantages of these rebars is their relatively low elastic modulus. GFRP rebars have less plastic area compared to steel rebars. After stress reaches the point of failure, instead of entering the plastic region, failure occurs. However, this weakness of rebars made of glass fibers becomes an advantage when using GFRP reinforcement in concrete. The elastic modulus of FRP rebars is more similar to concrete than metal, so the behavior of rebar against stress is consistent with concrete, and if you look at the performance comparison results of steel and composite concrete, you will see that concrete made of composite rebar has fewer cracks and suffers less damage while in use.

Types of FRP Rebar with Glass Fibers

Glass fibers are made by mixing silica sand, limestone, folic acid, and some other additives. The mixture is heated to about 1260 degrees Celsius until it melts. The molten glass is then allowed to flow through tiny holes in a platinum plate. Cold glass strands are collected and stretched in one direction to increase strength. The fibers are then woven into various shapes for use in composites. Due to the presence of compounds such as aluminum lime borosilicate, GFRP fibers are very good electrical insulators, have little sensitivity to moisture, and are an ideal choice for structural reinforcement. FRP rebars generally contain impact-resistant fibers, but their weight is more than carbon or aramid.

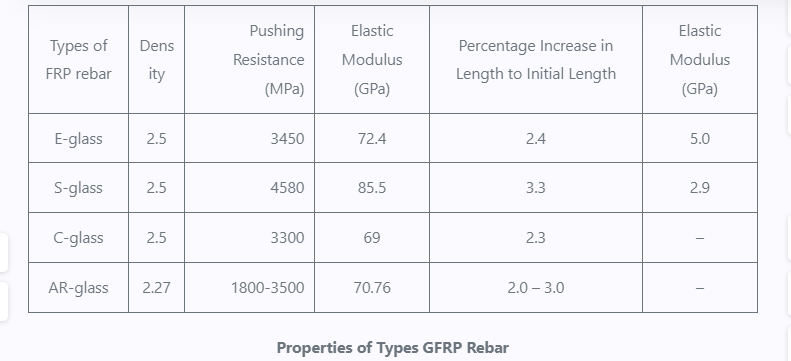

Types of GFRP rebar are:

- E-Glass

- S-Glass

- C-Glass

- AR-glass

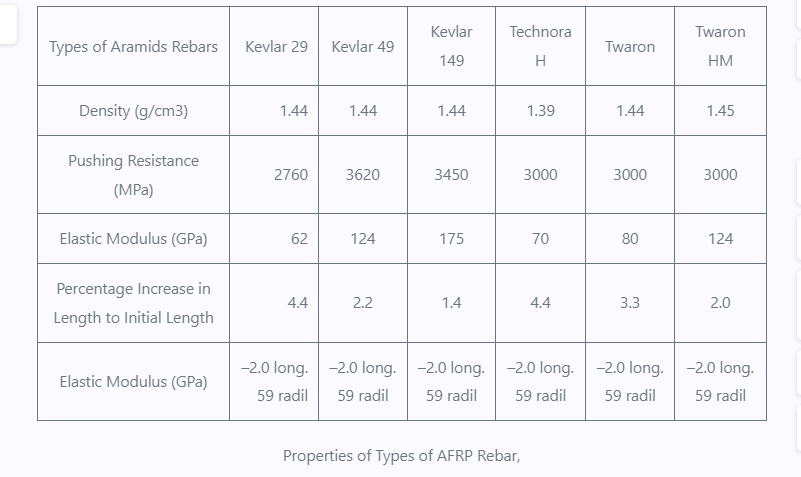

AFRP Rebar

Aramid fibers are anisotropic in nature. The color of these fibers is usually yellow. Aramit fiber is known as Kevlar fiber in the market. This fiber has the highest price compared to fiberglass and its main use is in conditions of extreme tension and does not have high compressive strength. In fact, AFRP rebar is mostly used for cables and other tensile items. These rebars are low in density and high in tensile strength and elastic modulus, and aramid rebars are also suitable in hardness. Two weaknesses related to the lack of plastic area and low radial strength have limited the use of these rebars. In addition, cutting these rebars is relatively hard and the processing is troublesome.

Types of AFRP rebars

Aramid is a type of aromatic polyamide, the common trademark of which is Kevlar, but other brands such as Twaron, Technora, and SVM are also available. The elastic modulus of the fibers is 200-700 GPa with a final elongation of 1.5 – 5% depending on the production quality. Aramid shows high resistance against breaking, therefore it is used for helmets and bulletproof clothes. These bars are sensitive to high temperatures, humidity, and ultraviolet rays, so they don’t have wide structural applications.

Types of FRP rebar made of aramid fibers are as follows:

Kevlar-29

Kelvar-49

Kelvar-149

Technora H

Twaron

Twaron HM

BFRP Rebar

Basalt fiber is a type of igneous rock that is formed by the rapid cooling of volcanic lava. The production of basalt fibers is similar to glass fibers. Crushed basalt stones are the only raw material needed to produce fibers. Basalt rebar is relatively new compared to other types of FRP rebar and has recently entered the market. These fibers have high tensile strength and good resistance and durability against high temperatures. These bars are one of the best options in structures that work with electromagnetic force. It has ideal resistance to corrosion and acid and is resistant to radiation, vibration, and UV. The application of BFRP is very limited compared to other types of FRP rebar.