Introduction for Aluminum Bars & Billets

Aluminum is a versatile metal that has become indispensable across a wide range of industries, including construction, transportation, packaging, and electronics. ARYAROD Export Company is proud to be a leading exporter of high-quality aluminum products such as round and polygonal bars, billets, and slabs. With a strong emphasis on quality, innovation, and customer satisfaction, ARYAROD has established itself as a reliable supplier to global markets. In this article, we will explore the various aluminum products offered by ARYAROD, their production methods, grading standards, dimensions, the history of aluminum production in Iran, export statistics, and target markets.

Aluminum Products Offered by ARYAROD

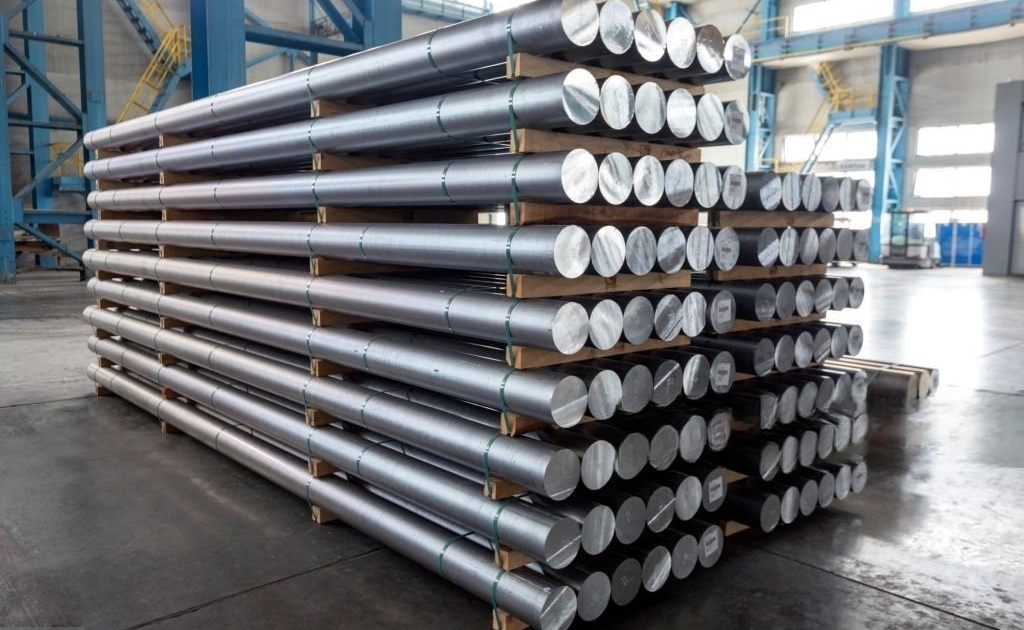

1. Aluminum Bars

- Round Bars: These are used extensively in manufacturing, construction, and transportation industries. Round bars are ideal for applications requiring precision and durability.

- Polygonal Bars: These bars are preferred for their unique shapes and enhanced structural integrity. They are commonly used in specialized engineering and architectural projects.

2. Aluminum Billets

Billets are semi-finished aluminum products used as raw material for extrusion and forging processes. They are essential for manufacturing various aluminum components, including pipes, tubes, and profiles.

3. Aluminum Slabs

Aluminum slabs are large, flat pieces of aluminum that are processed further into sheets, plates, and coils. These are widely used in the aerospace, automotive, and packaging industries.

Production Methods

1. Raw Material Sourcing

ARYAROD ensures the use of high-purity aluminum obtained from trusted suppliers. The raw material is meticulously tested to meet international standards.

2. Casting Process

- Direct Chill (DC) Casting: Used for producing billets and slabs, this method ensures uniform grain structure and excellent mechanical properties.

- Continuous Casting: Employed for certain types of bars, this process ensures high efficiency and reduced production costs.

3. Extrusion and Rolling

- Extrusion: Aluminum billets are heated and pushed through a die to create specific profiles, including bars and pipes.

- Rolling: Aluminum slabs are passed through rolling mills to achieve the desired thickness for sheets, plates, and coils.

Grading, Sizes, and Standards

Grading

ARYAROD’s aluminum products adhere to internationally recognized standards, including:

- AA Grades: These define the purity and alloy composition of aluminum.

- ASTM Standards: Ensure mechanical properties and chemical composition meet industry requirements.

Sizes and Dimensions

- Round Bars: Diameter ranges from 10 mm to 300 mm.

- Polygonal Bars: Customizable shapes and sizes.

- Billets: Lengths of 600 mm to 7,500 mm with diameters ranging from 90 mm to 600 mm.

- Slabs: Widths up to 2,200 mm and thicknesses from 50 mm to 600 mm.

The History of Aluminum Production in Iran

Aluminum production in Iran began in the mid-20th century, with the establishment of major smelting facilities. Over the years, Iran has invested heavily in its aluminum industry, leveraging its abundant natural resources and strategic location. Today, Iran is recognized as a significant player in the global aluminum market, with companies like ARYAROD contributing to the country’s export growth.

Export Statistics

ARYAROD Export Company has achieved remarkable success in exporting aluminum products. Some key highlights include:

- Export Volume: Over 50,000 metric tons of aluminum products annually.

- Revenue: Generating significant foreign exchange earnings for the Iranian economy.

- Global Reach: Supplying aluminum products to more than 30 countries worldwide.

Target Countries and Buyers

Primary Export Markets

- Middle East: Countries such as the UAE, Saudi Arabia, and Oman are major buyers of ARYAROD’s aluminum products.

- Europe: Germany, Italy, and Turkey are key destinations for aluminum billets and slabs.

- Asia: India, China, and South Korea are prominent importers, driven by their booming manufacturing sectors.

- Africa: South Africa and Egypt are growing markets for aluminum products.

Buyer Profiles

- Manufacturing Companies: Automotive and aerospace manufacturers rely on ARYAROD’s high-quality aluminum.

- Construction Firms: Builders and architects use aluminum bars and slabs for structural applications.

- Distributors: Wholesalers and distributors play a crucial role in delivering ARYAROD’s products to end-users.